HISTORY and CULTURE

In The News

Manufacturer of the Year – October 2025

Being a business owner is not about business. It’s about knowing your employees are smarter than you and considering their input. Its understanding that trust is built by continuous actions towards your customers. Its knowing that being respectful to those above, below, and around you IS the number one rule for business success. Life is a mirror, smile.

See More

___________________________________________________________________________________

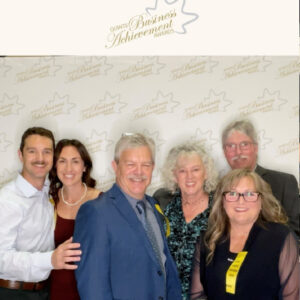

Quinte Business Achievement Award 2025

I got the opportunity to stand in front of a few hundred people last Friday to accepted an award on for manufacturer of the year. As a technical geek and tradeperson, public speaking isn’t my strong suit. I went off the cuff, but feel that there was a lot left to be said.

So many people I forgot to thank. So many stories of failure, trial, and success that I wanted to share but didn’t have the verbal articulation to express the emotional roller coaster of owning a business.

Fellow award winners had great speech’s that resonated with me, and one of the best speech’s of the night by Person of the year hit the nail on the head – “it feels like 99% failure and one percent success while running a business.” But here we are, making things work for that one percent – a satisfaction that is so exhilarating and so rewarding that justifies getting your ass kicked for the other 99% of the time. Being an entrepreneur means that you are a serial problem solver. When you deal with problems all day, failure is inevitable. It’s no doubt that the award winners share a common theme of failing their way to success.

Having a fear of public speaking, I pulled together enough bravery to thank the core group of individuals that made it happen for Donmac Precision Machining. The founders of the business that have, (consciously or not) showed me the grit it takes to be successful. The vision and hard work it took to get Donmac here set the foundation for who we are today. Whether we wanted the lessons or didn’t want the lessons my parents, Glenn and Joan installed their values and work ethic into their children.

As with any small business, we are nothing without our dedicated staff. They are truly our family away from home. We work well together, and we celebrate each others milestones and accomplishments. True dedication and “do what it takes” mentality is led by long time employee / now business partner Jamie Smith. She is truly dedicated to Donmac’s solution providing approach and leads our team as an equal. Jamie and I have hand packed our skilled staff because they have the ability to find the way when our competition cannot. These individuals truly think outside the box – which can be tricky, considering most of what we make requires magnification to inspect it. Our staff is our greatest asset and knowing what needs to be done before management does earns us accomplishments like this.

Another comment theme from all 13 award winners on Friday night was the gratitude they had towards their partner. It takes just as much positivity and a lot more patience to be married to someone who never stops thinking about work problems. My mom showed me how it was possible, and my wife, Morgan astonishes me every day and how she handles me and our two wild boys.

Being manufacturer of the year was not on our radar, we were not prepared to stand on stage and accept the award, but we are gracious that the Quinte region supports what we do and has our back the moment we reach out. We are not involved with local customers, our global reach sometimes pulls us away from being more involved with our local community and yet our local organizations (many of them Event sponsors like Quinte manufacturing association) continue to assist us at without asking anything in return. On Friday night I had the chance to speak in front of some VIP’s, we have had the plant visits from the Mayor and now we have been awarded Manufacturer of the year – all for just doing our daily duties the only way we know how.

Quality first and above all else.

Delivering solutions on time to keep our customers production lines running.

And as always, continuously improving every job we take on.

In closing, If I was a public speaker like many of the other award winners on Friday night, that is the speech I would have liked to say. However, I’m a tradesperson and my skills are working with my hands and collaborating technical solutions with likeminded individuals. I get up in the morning and I solve problems. I graduated high school only because I could get out in the workforce for an electrical Co-Op. After I was a licenced electrician, I moved into overhauling power generators and now I am honoured to spend my days working with incredible smart people making raw materials into precise & mission critical components used in human surgery, aircraft controls or even on the battlefront.

Being a business owner is not about business. It’s about knowing your employees are smarter than you and considering their input. Its understanding that trust is built by continuous actions towards your customers. Its knowing that being respectful to those above, below, and around you IS the number one rule for business success. Life is a mirror, smile.

Embracing Environmental Changes – 2025

Canadian Company Embraces Environmental Changes Required for Future Use of Solvent Degreasing

See More

___________________________________________________________________________________

Canadian Company Embraces Environmental Changes Required for Future Use of Solvent Degreasing

By Travis Donaldson – Donmac Co-Owner

Technical Advisors:

-

Eric Bromley – KYZEN Canadian Regional Manager

-

Joe McChesney – KYZEN Global Products Line Manager – Solvents

History

Donmac Precision Machining is a growing organization providing various metal components “made to order” for Aerospace, Medical, and Defense customers around the world. They are a well-respected member of the Precision Machined Products Association – an international trade association.

Most of the manufactured parts are used in critical applications where failure is not an option. These components must perform reliably 100% of the time. Donmac has built its reputation on precision quality and the ability to deliver what is promised.

As a provider of various types of assemblies and components, some lubricants used in manufacturing processes are more thoroughly and easily removed when using a solvent versus an aqueous process. Donmac had an older generation degreaser that used 1-Bromopropane (nPB) – a bromine-based solvent.

Due to evolving changes in environmental issues in Canada and other areas of the world concerning the use of 1-Bromopropane solvent (better known as nPB), Donmac decided to address the existing use of this solvent from several aspects.

First, they wanted a solvent that would provide a more environmentally favorable application for their parts requiring solvent degreasing. A major item was safety for their employees. Any new solvent selected had to provide increased levels of safety (operator exposure limits) over the old nPB solvent as well as meet Canadian Environmental Protection Act standards for air pollutants. nPB solvent has been targeted for more stringent regulations and was banned in Europe in July 2020.

Next, Donmac wanted a solvent that would provide flexibility for various types of lubricants while being compatible with different machined materials. They needed a solvent that was stable and operated at a medium temperature range for energy conservation.

Replacement Criteria

-

Be safe for workers

-

Meet Canadian environmental regulations

-

Be a long-term, sustainable chemistry

-

Clean as effectively as current processes (nPB)

-

Not interfere with following processes or inspection methods

-

Could be used in existing degreaser system

The Cleaning Process

Donmac utilizes a vapor degreasing cleaning process using a solvent for contamination removal prior to the following processes or inspection. These contaminants include cuttings, fingerprints, oils, and particulates. Total contamination removal is required on the substrate surface. To provide thorough part inspection, a very robust cleaning process ensuring 100% soil removal is required. Environmental regulation has forced Donmac to find an alternative solvent for the degreasing process.

Donmac selected KYZEN METALNOX M6900 as their new solvent. This solvent offers the following features:

-

Non-flammable

-

Not a HAP (Hazardous Air Pollutant under USA EPA definition)

-

Personnel Exposure Limit (PEL) of 200 ppm vs 0.10 for nPB (2,000× safer)

-

No additive stabilizers required

-

Boiling point 112ºF vs. 160ºF for nPB (energy savings)

-

Environmentally friendly rating

To further improve Donmac’s process, they purchased a new state-of-the-art vapor degreaser to replace their existing older generation system. The new degreaser improves solvent conservation through design efficiencies including a rotating work basket system that enhances cleaning and drainage.

New Solvent Technology

KYZEN METALNOX M6900 is a new solvent offering exceptional cleaning power in vapor and immersion applications while satisfying environmental and safety requirements. It is non-flammable (ASTM-E681).

EPA and OSHA Ratings:

-

Ozone Depletion Potential: 0.03

-

Global Warming Potential: 148 (100-year ITH)

-

Flash Point: None

-

Personnel Exposure Guidelines (8 hr. TWA): 200 ppm

-

VOC Content: 896 g/L (t-DCE content)

-

Reportable Quantity (spill): 1000 lbs (t-DCE)

-

Regulated if emitted into water: Yes

-

Hazardous Air Pollutant: No

-

Annual Reporting (SARA Section 355): No

-

OSHA list of toxins/carcinogens: No

Cleaning Performance:

-

Excellent cleaning ability with common soils

-

Superior wetting – cleans tight spaces

-

Compatible with metals (aluminum, copper, titanium, magnesium, alloys)

-

Recoverable or recyclable via simple atmospheric flash distillation

-

Very stable – resistant to thermal and hydrolytic breakdown

Solvent Purity and Soil Management

When using solvent to clean parts, maintaining efficiency requires clean solvent. Purchasing new solvent is costly, and waste disposal is regulated and expensive.

As parts are cleaned, contaminants accumulate in the boil sump. To maintain purity within acceptable ranges, contaminants must be removed regularly.

An in-house solvent recycle system enhances purity, improving final cleanliness and providing substantial cost savings by extending bath life and reducing waste volume and disposal costs.

Donmac incorporated this system into their new degreaser operation to enjoy improved solvent quality and reduced waste generation.

KAPTURE Functionality

-

Laboratory testing has proven the KYZEN KAPTURE system to be 98% efficient in removing typical soils found in solvent cleaning.

-

Traditional “cook-downs” occur at roughly 12% soil loading (every 4–6 weeks). This traditional approach requires downtime and maintenance, all of which change with the autonomous KAPTURE system.

-

By automatically removing soils from the boil chamber continuously, KAPTURE maintains solvent purity at high levels, enhances cleaning action, and extends bath life considerably.

-

Waste is greatly reduced. Waste is automatically separated from solvent for periodic disposal. Maintenance is minimal—simply replace the 5-gallon waste vessel when the alarm notifies you.

Results

Donmac successfully replaced a solvent and older generation degreaser with a more environmentally friendly system that provides EHS advantages and performance.

Summary

KYZEN METALNOX M6900 is a safe and effective choice for cleaning parts in the precision machining industry and has been proven by Donmac to completely remove all contamination. It combines non-flammability, low toxicity, and high cleaning performance while cleaning tight spaces efficiently.

By adding the KYZEN KAPTURE, Donmac achieved operational cost savings and improved solvent quality.

“With the KAPTURE distillation system, we don’t ever have to worry about replacing expensive solvent or cleaning parts in a cleaner that’s saturated with oil like we did in the past. Other than the quick bi-monthly dump, we set it and forget it. It’s worry-free and pays for itself in recycled solvent.”

— Travis Donaldson, Co-Owner, Donmac Precision Machining

For more information: Travisd@Donmac.net

Keeping It In The Family With Travis Donaldson – January 2025

Keeping It In The Family With Travis Donaldson of Donmac Precision Machining Inc.

Miles Free, Carli Kistler-Miller, and David Wynn are joined by Travis Donaldson of Donmac Precision Machining Inc. where the discuss his experience of passing the business torch from one family member to another.

See More

___________________________________________________________________________________

See podcast here:

Keeping It In The Family With Travis Donaldson of Donmac Precision Machining Inc.

Related Articles:

Next Generation of Manufacturing and Technology- 2021-2022

Donmac Precision Machining Inc. has room to grow – in their brand-new Foxboro, Ontario facility and into the new technology that the next generation of machinists and manufacturing technicians want to use. For the last 34 years, Donmac has created mission critical components for defense, aerospace, medical and electronics markets. Donmac’s growth has never been more obvious than over the last 5 years, when Donmac has been growing their capabilities in the defense and medical industries; their latest projects include complex assemblies for a large project involving Navy ships. These industries require tighter tolerances, faster lead times, and more complex parts requiring better capabilities, faster setups, and more machine time from Donmac.

See More

_________________________________________________________________________________

Donmac Precision Machining Inc. has room to grow – in their brand-new Foxboro, Ontario facility and into the new technology that the next generation of machinists and manufacturing technicians want to use. For the last 34 years, Donmac has created mission critical components for defense, aerospace, medical and electronics markets. Donmac’s growth has never been more obvious than over the last 5 years, when Donmac has been growing their capabilities in the defense and medical industries; their latest projects include complex assemblies for a large project involving Navy ships. These industries require tighter tolerances, faster lead times, and more complex parts requiring better capabilities, faster setups, and more machine time from Donmac.

Out With the Old, In With The Next Gen of Manufacturing Tech

Donmac decided to embrace new technologies that would allow faster setups and tighter tolerances then their multi spindle machines. The new technology includes a complex CNC Lathe with auto-loading and unattended machining capabilities. Some of the high demand features of this machine include:

1. Automatic bar loading system which automatically removes old workpieces and inserts new raw materials

2. LFV (low frequency vibration) cutting technology which allows Donmac to machine exotic materials that are prone to build up. The LFV cutting action breaks up the build up to stop clogs from forming within the machine, and allows for fewer to no operator interventions while the machine is running.

3. Conveyor system that carries the finished product out of the machine to the machining bay and into the operator inspection basket, so it can be inspected and passed to the next step in the process without stopping the machine.

4. Chip conveyor which evacuates cuttings so that the machine can continue production without being stopped for clean out.

Supported by QTAP (Quinte Technology Adoption Program), Donmac was able to make the switch from their out of date multi-spindle machines to the new CNC Lathes and have witnessed growth and efficiency improvements for the company. The CNC Lathe with auto-loading and unattended machining technology have:

Given Donmac the ability to compete with US competitors

Improved run time by allowing Donmac to run the machine for longer periods without attending to the machine – the “unattended machining”

Improved operator training time since, with the new CNC Swiss lathes there is a network of solutions, including YouTube channels and Facebook groups, to help users with programming and machine set up

Off-site training is also available, a feature that no longer existed with Donmac’s older technology

Increased sales by taking on more complex work, as well as made up for profit losses after Donmac retired the multi-spindle machines

Grown their customer base allowing them to expand their reach into medical markets, which have tight tolerances and require exotic materials

Created jobs by allowing Donmac to hire 1 new machinist and 1 new apprentice

Donmac’s success can be attributed to their understanding of the changes in the industry and their decision to improve with QTAP. Successful applicants to QTAP could receive up to 50% funding (to a maximum contribution of $10,000) for new technology acquisitions.

Stuff Made and Built in Eastern Ontario -2021-2022

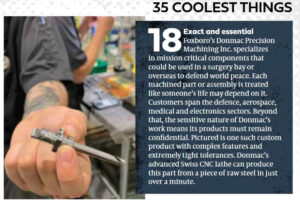

Exact and Essential

Foxboro’s Donmac Precision Machining Inc. specializes in mission-critical components that could be used in a surgery bay or overseas to defend world peace. Each machined part or assembly is treated like someone’s life may depend on it.

Customers span the defence, aerospace, medical, and electronics sectors. Beyond that, the sensitive nature of Donmac’s work means its products must remain confidential.

Pictured is one such custom product with complex features and extremely tight tolerances. Donmac’s advanced Swiss CNC lathe can produce this part from a piece of raw steel in just over a minute.

See More

_________________________________________________________________________________

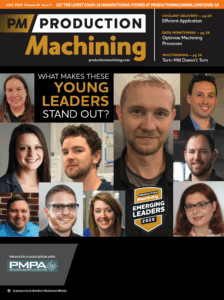

Role Model Leads Shop to New Growth – August 2020

What makes these young leaders stand out?

See More

___________________________________________________________________________________

Production Machining magazine – July 2020

What makes these young leaders stand out?

See More

___________________________________________________________________________________

Belleville Community Magazine – January 2019

The Donmac Precision team, which originally consisted of three people, is now ten full-time employees and continues to grow. Their business growth has also resulted in the construction of a new 12,000 square foot facility (scheduled to open in the spring of 2019) right next to their current location on Ashley Street in Foxboro. The lay out of the new facility will provide the Donmac team of machinists, design engineers, quality controllers, quality assurance and shipping and receiving professionals the space to streamline processes.